Three ways to check compliance

There are a number of ways to check compliance to AS/NZS 3678:2011.This includes correct compliance information being noted on both plate stencils and test certificates, and for further assurance, ACRS Certification.

BlueScope Steel is Australia’s only manufacturer of flat steel and has a long history of supplying quality products that meet or exceed Australian Standards at its ISO:9001 accredited manufacturing facilities.

Compliance to the Standard is vital as it gives the specifier and purchaser confidence that the material obtained will perform as intended in the design and use phases of the project.

Unfortunately reinforcing, prestressing and structural steels have arrived on construction sites within Australia that fail to meet the minimum requirements of the applicable AS/NZ Standards.

The influx of these non-complying materials have led to lengthy project delays and consequential rectification costs. In addition, companies and individuals may be liable under the Work Health & Safety Act 2011 in the event of structural failure causing injury or death, occurring as a result of using non-compliant materials.

Some of the key problems have been identified. Problems include inadequate product traceability; misleading and false supporting documentation; excessive variation in materials properties and product markings that are simply inadequate.

BlueScope Steel supports a safe construction and fabrication industry. Therefore we would like to provide information that will assist you to ensure that the material you specify is actually supplied; in this way we are assisting you to protect your reputation.

BlueScope Steel has identified a number of ways to check compliance to AS/NZS 3678:2011. This includes correct compliance information being noted on both plate stencils and test certificates, and for further assurance, ACRS Certification. ACRS has independently assessed BlueScope Steel to have the capability to manufacture to Australian Standard AS/NZS 3678 and verified that it consistently does so.

Three ways to check compliance

1. Check the stencil on the plate has the following minimum information:

- Steel grade and the Standard applicable

- Heat number

- Traceable plate or identification number

- Name of manufacturer

BlueScope Steel stencils all of its AS/NZS 3678 structural steel plate with the necessary compliance information for identification, traceability and linkage to a specific test certificate. Although not mandatory, the stencil also states the ACRS certification number for even greater assurance.

Having the right information as required by the Standard provides the first step in the quest for product compliance assurance.

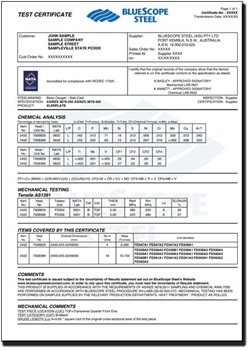

2. Check the test certificate has the following minimum information:

- Certificates to be written in English

- Reference to a third party accrediting body recognised by ILAC, such as NATA

- Steelmakers, manufacturers, suppliers and testing authorities name

- Test certificate number and test number

- Date

- Product, testing specification and grade, e.g. AS/NZS 3678-350L15

- Product delivery condition, e.g. “As rolled”

- Dimensions

- Product Steelmaking process, e.g. basic oxygen, slab cast

- Unique product identifiers for the tested units and other product covered by the test certificate

- Heat number

- Chemical Analysis type, e.g. either ladle or cast analysis ('L') or product ('P') analysis

- Chemical composition of all elements listed in Tables 2 or 3 of the standard

- The relevant mechanical testing results (including test piece position and orientation, batch or item basis of testing and results)

- Additional tests agreed between the purchaser and the manufacturer

- Statement acknowledging the chemistry and tested mechanical properties comply with the standard

- Signatory from the manufacturer, supplier and certification authority attesting to items above

NATA accredited test certificates are provided with each BlueScope Steel order and are kept on file. Certificates dating back to 1993 are available online for uncoated steel, and provide a strong second step in the quest for product compliance assurance.

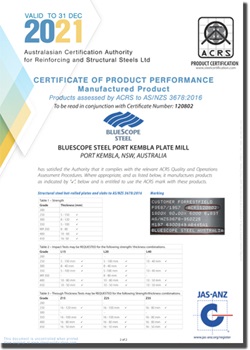

3. ACRS Certification - BlueScope Steel is now ACRS certified:

When you specify BlueScope steel you can be confident that you get the quality you have specified, and not potentially non-compliant materials that put you at risk.

To provide the third step in assuring specifiers and customers that our XLERPLATE® steel meets or exceeds AS/NZS 3678, ACRS has independently assessed BlueScope Steel to have the capability to manufacture to Australian Standard AS/NZS 3678 and verified that it consistently does so.

For a print friendly version, download Assuring Product Compliance - Three Ways to Check (1791 KB)

What is ACRS?

The Australasian Certification Authority for Reinforcing and Structural Steels (“ACRS”) provides independent, expert, industry-based accreditation, certifying manufacturers and suppliers of reinforcing, prestressing and structural steels to Australian/New Zealand Standards.

ACRS was formed by industry in 2000, using an internationally recognised model for steel certification established in the UK almost 30 years ago. ACRS is structured around the requirements of the International Standard for bodies operating product certification systems, ISO/Guide 65, published as AS/NZS 3843, and its successor Standard, ISO/IEC 17065.

ACRS currently certifies over 150 manufacturing locations, in 15 countries around the world, and has undertaken more than 500 technical conformity assessments to AS/NZ steel Standards.

For more information, visit: www.steelcertification.com

BlueScope Steel ACRS certification - The key benefits to you

- ACRS has independently assessed BlueScope Steel to have the capability to manufacture to Australian Standard AS/NZS 3678 and verified that it consistently does so

- Mitigates risk and protects your reputation. You can be confident that the material you specify will deliver the properties outlined under AS/NZS 3678 – properties you are assuming when designing for critical applications; a basic prerequisite to mitigate failure in service

- It enables your procurement choices to be made on a compliance basis and not simply on the cost of an “equivalent” product