Milson Island Sports & Recreation Centre

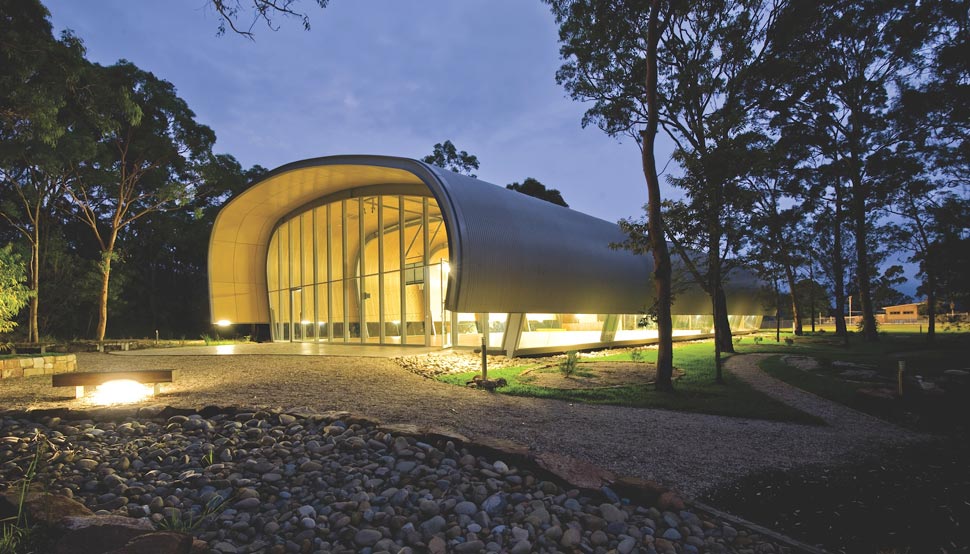

An upturned ‘boat’ on a carefree island is the perfect escape for kids on holidays.

Credentials:

Client: Sport and Recreation New South WalesArchitect: Allen Jack+Cottier

Project Team: Design: Michael Heenan; Project Director: John Whittingham; Project Architect: John Gunnell; Architect: Jennifer Gerbauer

Structural Engineer: Taylor Thomson Whitting

Builder: Inten Constructions

Steel Fabricator: DesignedBuildingsystems

Shop Drawing Contractor:Centreline Drawing Services

Cladding Contractor:Sam’s Roofing

Landscape Architects: Environmental Partnership

Awards:

AIA National COLORBOND® Award for Steel Architecture, 2012.

AIA NSW Chapter - COLORBOND® Award for Steel Architecture, 2012.

AIA NSW Chapter - Commendation for Public Architecture, 2011

Master Builders National Excellence in Building and Construction Awards: National Commercial / Industrial Construction Award – under $5 million, 2011.

Building Size: 690m2 (floor area)

Total Project Cost: $2.7 million

Words: Rob Gillam

Related Content: Q&A with Martin Rogers, associate director at Taylor Thomson Whitting

Located in the picturesque Hawkesbury River north of Sydney, Milson Island was once a hospital and a jail but is now a playground for primary school children. Sport and Recreation NSW hosts groups of up to 180 kids who ‘camp’ there for a week and enjoy activities like canoeing, fencing, climbing and high ropes.

Asked to build a recreation centre with a modest budget, Allen Jack+Cottier principal Michael Heenan wanted to demonstrate that great buildings can be made with limited funds. “It’s good working with clients who expect grand results,” he says. “We like a challenge: it encourages us, and fortunately we know some ways to save money by working smarter.”

All of the construction materials had to be barged to the island prior to building, making steel a natural choice, Heenan says. “We did investigate the possibility of using materials other than steel. We modelled some different materials but nothing could match steel’s contributive strength and lightness, so it was an ideal choice given our building constraints.”

Working smarter involved combining steel structure and cladding to accomplish at least three objectives: to achieve passive cooling and ventilation inside, to carry wind loads outside, and to reduce structural forces by about 30 per cent, thereby cutting costs by a similar margin, Heenan says.

The structural steel bracing is integrated with the upturned hull-like roof, which is clad with LYSAGHT CUSTOM ORB® profile made from COLORBOND® Ultra Steel in the colour Dune®.The roof forms a protective shell that acts as a fire-deterrent skin, and the absence of gutters – leaf litter simply slides off the COLORBOND® steel and onto gutters in the ground – meant that Heenan could position the hall within a thick clump of trees.

He finds it ironic that the semi-elliptical building has been called a ‘wonky’ shed, given all the analysis that underpinned its creation. “There’s a lot of thinking and a lot of scientific modelling behind this thing with the capabilities of steel,” he says. “The building’s shape is almost like a boat’s hull in reverse. Someone joked that we could have built it on shore and floated it over upside down.”

As well as being informed by the site and its attributes, Heenan drew inspiration from images of Arnhem Land aborigines making their canoes out of tree bark, braced with sticks, and the way they upturned those canoes to form shelters on land. “This project shares design similarities in the way it responds to the predominant western breeze,” he explains.

“I tried to reflect the essence of shelter, the simple poetry of a piece of bark leaning on the ground, it’s just that our ‘sticks’ happen to be steel.”